+7 (929) 727 53 60 Traumatology / Orthopedics / Neurosurgery

Allogenic tissue bank and research center SamSMU

- The Samara Textile Bank is based on the Central Research Laboratory (CSRL) of the Samara State Medical University (SamSMU).

- In 2013, the Samara Bank of Fabrics celebrated its 30th anniversary, and the Central Research Laboratory - the 50th anniversary.

- LYOSELL is a small innovative enterprise established on the basis of the Samara tissue bank.

- "LYOPLAST" - products of the company "LYOSELL".

- Bioimplants are used in 80 regions of Russia, 135 cities and more than 1000 medical institutions.

1. Brief information sheet on the production of alloplastic materials Lyoplast-C technology

The production of bio-implants "Lyoplast®" is organized in Samara State University with the participation of the central research laboratory and the Samara tissue bank, which are structural units of the University.

In the Samara bank of fabrics the original algorithm of manufacturing of biological products from human tissues is used, protected by patents of the Russian Federation.

At the first stage, the process of obtaining implants involves a special ultrasonic tissue treatment to remove bone marrow and fat from spongiosis, carry out primary sterilization of the material, viral inactivation.

After the initial treatment, the tissues are lyophilized, and then the hermetically sealed material is sterilized by radiation.

In addition, the use of low-frequency ultrasound allows saturating bioimplants from human tissues with various antibiotics and antiseptics, fungicides.

Within the framework of a closed cycle of waste-free production, specialists in a tissue bank simultaneously receive two types of new materials: demineralized bone forms and the mineral component of human bone tissue - “allogeneic hydroxyapatite”.

The obtained mineral-containing complex, in addition to calcium and phosphorus salts, contains other trace elements (iron, magnesium, cobalt, zinc, silver), as well as glycosaminoglycans in the same proportions as they are in human bone tissue (collagen and chondroitin sulfate).

The principle of differentiated selection of bone bioimplants, developed by the university, which is based on the anatomical-histological and regenerative potencies of damaged epithelial and connective tissues, ensures complete regeneration of the patient's damaged bone tissue and preserves the anatomical integrity of the organ.

The use of new and already known types of implants in combination with the proposed methods of regulation of postoperative processes allowed reducing the treatment time of patients by 10-12% compared with traditional methods, increasing the percentage of successful recovery (for example, for fractures of the femoral neck in the elderly) by 44 %

Together with clinicians of various specializations (dentists, otorhinolaryngologists, ophthalmologists, traumatologists, orthopedists, oncologists, purulent and plastic surgeons, combustiologists) developed new methods of minimally invasive and low-traumatic organ-preserving operations using allogenic forms. , dentition, skin, vision and hearing, for the treatment of osteoporosis.

Original operations using video endoscopic techniques and bioimplants are used in sports medicine.

The use of lyophilized "Aloplast" Lyoplast® ® showed their high efficacy in the complex surgical treatment of many diseases in people of different age groups.

To date, the results of allogeneic transplants using our materials and techniques are very close to the results with autoplastic. At the same time, there are no disturbances of homeostasis, stress and post-traumatic complications associated with the collection of the body’s own tissues.

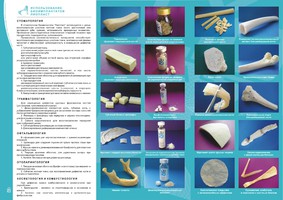

The urgent need to open a tissue bank in Kuibyshev (now the city of Samara) appeared in the 70s of the last century.

At that time, traumatology and dentistry actively developed at the Kuibyshev Medical Institute, therefore the need for biological material was obvious.

The idea to organize the Tissue Bank at the medical university belongs to the academician of the RAMS Alexander Fedorovich Krasnov, who at that time headed the institute and the department of traumatology and orthopedics. There have been repeated attempts to open such a structure.

But only after professor Vladimir Nikolaevich Shlyapnikov, the vice-rector of the institute who was in charge of the Central Research Laboratory from 1970 to 1977, the pathologist with a specialty, proposed to deploy a tissue bank on the basis of the Central Research Laboratory of the Kuibyshev Medical Institute .

The tissue bank was established in 1983. At the beginning of its existence, it consisted of a single unit - the Department of tissue conservation. Its discovery is dated by the order of the KMI and the regional department of health No. 285/48 of August 18, 1983.

Since 2000, a cell culture laboratory has been organized in the structure of a tissue bank, within which there are two separate laboratories: animal cells and human cells.

On March 6, 2002, the Department of Tissue Preservation was renamed the Samara Tissue Bank (order No. 40 for SamGMU). Kuibyshev Tissue Bank became the only one in the country located in the structure of a higher educational institution.

In the first decade of work of the Kuibyshev tissue bank for the manufacture of biological preparations, liquid preservative media were used, in particular, the domestic preservation method in weak formalin solutions (Parfentieva V.F. and co-authors).

This affordable, inexpensive and effective way allows you to simultaneously preserve and sterilize the material.

In addition, as shown by our own research, biological tissues thus preserved acquire an additional antimicrobial effect.

However, their shelf life is limited to six months, there are difficulties with transportation, requires constant temperature storage (+ 40C).

Therefore, it became necessary to produce osteoplastic material with long shelf life and the possibility of their simple application in clinical practice.

Subsequently, the Samara tissue bank switched to a method of preservation by lyophilizing tissues using a sublimation unit, followed by radiation sterilization with gamma rays, and more recently with fast electrons.

This method allows you to save the biological effect of tissues up to 5 years or more, store them in ordinary rooms and ship them to anywhere in the country and the world without special delivery conditions.

Our scientific and practical developments allowed us to reach the international level. In 1992, the first international contract was signed with Spain.

Thanks to foreign investments, it became possible to expand research in the field of tissue engineering and implement innovative projects.

Since 1992, high-tech production of lyophilized bioimplants has been organized.

As a result, our new biomaterial manufacturing technologies were patented, a trademark was registered (certificate No. 265748), and Lioplast biomaterials were entered into the federal register of medical products (RU FFS No. 2010/08120; Certificate No. РОСС RU ИМ 02.В16812) and allowed for use in clinical practice in the territory of the Russian Federation.

It was the scientific and technical base at that time of the Central Scientific Research Laboratory, now IEMB, which includes a block of research laboratories of the fundamental plan, experimental department, vivarium, excellent conditions for conducting experiments on animals and cell cultures, ensured the implementation of innovative projects of the Samara tissue bank and comprehensive preclinical testing of new biogenic samples.

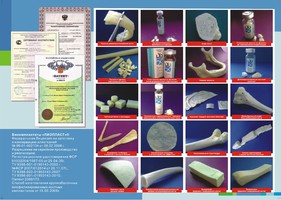

Currently, about 100 types of Lioplast implants are made for medical purposes in the Samara Bank of Tissues - from virtually all types of connective tissue, varying in shape and volume of biomaterial in a package.

They are derived from mature lamellar bone tissue of the spongy and compact formations, immature brefokosti, cartilage, tendons, fasciae, dura mater, and also before the placenta and amnion.

The bulk of products "Lyoplast" are osteoplastic materials. The preparations are produced in the form of blocks, cylinders, plates, strips, chips, powders.

3. Tissue Bank in Samara and the Central Research Laboratory, Institute for Innovative Development

The Institute of Experimental Medicine and Biotechnology (IEMB) has been dealing with the problems of regenerative medicine for 50 years and there is a tissue bank of Samara State Medical University for more than 30 years.

The tissue bank should be recognized as a Russian achievement, because unlike other banks, it was created on the basis of the university in order to create reserves of all-material for the clinic, to develop new technologies, which initially implied its innovative principle.

Currently, his activity has gone far beyond the limits of Samara State Medical University to other regions of the Russian Federation, as well as the near and far abroad.

Initially, the work of the Samara Bank of Textiles was based on the principle of the separation of production zones with the collection of non-sterile donor material.

This was made possible thanks to the original patented technological process developed and implemented by us, which includes special treatment of cadaver tissues, primary disinfection, including viral inactivation of biological material and its preservation by lyophilization.

At the same time, special importance is attached to the use of mainly physical factors influencing the biomaterial and minimizing chemicals.

The introduction of the ultrasonic low-frequency module into the technological process, which allows not only to degrease and clean from blood and other types of connective tissue, to carry out the primary sterilization of the biomaterial, but also to create a line of products with prolonged antibacterial and anti-fungicidal properties.

Sterilization of finished products abroad is carried out with ethylene oxide.

This problem has been solved by radiation methods in the Samara Bank of Fabrics; their experience has been used for 20 years.

Only in recent years, the world practice of harvesting human allotques has shown the advantage of radiation methods, which has become the “gold standard”.

Due to the location of the Tissue Bank on the basis of the Institute of Experimental Medicine and Biotechnologies (IEMB) with the existing subdivisions and being a structural subdivision of SamSMU, it became possible to conduct basic research on the regulation of regenerative processes in supporting and integumentary tissues of humans and animals with differentiated use of cellular and tissue biotechnology products.

All studies are conducted on a two-step basis - in vitro and in vivo using original experimental models and an integrated approach to the evaluation of the results obtained using modern methods of analysis.

A characteristic feature of our time is the development of reconstructive and regenerative medicine.

In traumatology, orthopedics, dentistry, oncology and purulent surgery, the search for approaches to the treatment of the pathology of the supporting and integumentary tissues of the human body and involves not only means of its elimination, but also achieving the original form, structure and function of destroyed bones and injuries.

Ensuring complete regeneration of bone tissue in the area of defective bone areas, despite the accumulated knowledge in this matter, is one of the most acute problems of modern medicine.

It can be solved by creating optimal conditions for regenerative processes in the areas of its resorption. One of the ways is the use of osteoplastic materials.

Tissue bioengineering technologies and tissue therapy, the use of various components of human tissues are generally recognized highly effective methods of reconstructive and regenerative surgery.

The modern level of development of science and technology allows for the damage and destruction of the supporting and integumentary tissues of the body to produce their full restoration with the help of preparations of biogenic nature.

Among them, allogeneic implants from human cadaveric tissues are the best materials for the reconstruction of damage to the musculoskeletal system.

In their application, in contrast to auto- and xenoplasty and the use of synthetic drugs, the homeostasis and metabolism of connective tissues and the function of the life-support systems of the recipient are not disturbed.

The expansion of the volume of surgical benefits associated with obtaining bone marrow autograft in a sick person not only aggravates the course of the postoperative period, but also causes significant disturbances in the body.

Autoplasty is not possible for persons with systemic bone diseases, children and the elderly. The results of surgical interventions using allogeneic bioimplants under certain conditions are not inferior to osteoplasty using the patient's own tissues.

With a rational method of application, such bioimplants provide reparative regeneration, realizing the genetic capabilities of the organism itself - the ability of connective tissues to fully regenerate them.

The problems of harvesting human tissues and the development of methods of rational use in the clinic are engaged both in our country and abroad special medical institutions - tissue banks.

The activity of tissue banks is aimed at the formation of stocks of biological materials and the provision of specialized medical institutions with them.

Another equally important task is research work, the purpose of which is to solve the pressing problems of fundamental and applied bioimplantology.

Thus, the tasks of the tissue banks themselves determine the innovative nature of their activities.

This is confirmed by the results of the scientific and practical activities of the Samara tissue bank, which is actively pursuing new developments in the field of tissue and cell technologies with the commercialization of scientific ideas.

Alexey Sharov: Good afternoon, dear friends! Today we are in the city of Samara and we will talk about the domestic innovative product. These are the bioimplants "Lyoplast-S" ® (Lyoplast) ®. And the author and developer will help us in this, - Larisa Volodova, MD, professor, academician of RAE, director of IEMB (Institute of Experimental Medicine and Biotechnologies) of Samara State Medical University.

Alexey Sharov: Larisa Teodorovna, are there any priority areas in your institute?

Larisa Teodorovna Volova: Within the walls of IEMB, they are engaged in various fields in the field of biotechnology. For over 30 years we have been working in the field of tissue technology, about 12 years in the field of cellular technology and 7 years in the field of nanotechnology.

In particular, such new medical technologies have been developed for the regulation of osteogenesis in slow consolidation and periodontitis, osteoporosis, skin burns, and injuries. Our products are used to create cell-tissue grafts for chondroplasty and research in space medicine.

They are not only a carrier of cells, but also a bioreactor, and are also capable of performing formative and genetic functions.

We also developed technologies for obtaining and standardizing cell cultures from the stroma of various organs and tissues of animals and humans; testing methodology for various drugs and medical supplies, in vitro physiotherapeutic factors.

Our priorities in the institute are: regenerative medicine and critical biotechnologies. We have three laboratories for basic research: biochemistry, immunology, and morphology. The biotechnology department has a tissue bank, two laboratories: the cultivation of animal and human cells.

Alexey Sharov: What qualities does Lyoplast-S ® possess?

Larisa Volova: Allogeneic implants from human cadaveric tissues are ideal for reconstruction of damaged tissues of the musculoskeletal system, as they do not adversely affect the homeostasis and metabolism of connective tissues and the functions of the recipient’s life-support systems.

What can be said about synthetic preparations, auto- and xenoplastic materials.

Allogeneic materials taken from a donor of the same species after their special treatment almost completely lose their antigenicity and do not adversely affect the organism in which they are placed.

They become a matrix (conductor), and demineralized implants are also an inducer of osteogenesis. Bioimplants are gradually completely absorbed, and in their place a new organotypic bone tissue of the recipient is formed.

In all cases, the bioimplant contains osteoinductive proteins (morphogenetic proteins) that stimulate, for example, mitogenesis (division) of undifferentiated perivascular (adventitious) cells into osteoprogenital mesenchymal cells, which then turn into osteoblasts and give rise to new bone tissue.

Our material has been known abroad for more than twenty years. From 1992 to 2000, I have experience working with partners from Spain. However, the lengthy procedure for Russia's entry into a single trade union and the WTO has slowed down the penetration of material into the world market.

In addition, there was a ministerial ban on the export of human tissue and biological objects, under which we also fell. Today, these barriers have been removed and we have dozens of preliminary contracts with domestic and foreign companies.

And we are united by creative and business contacts with 80 regions of our big and beautiful country.

Alexey Sharov: Why do you prefer to make bioimplants from human tissues?

Larisa Volova Theodorovna: Cadavier human material is preferred for a variety of factors.

First, it is a homologous material.

It is completely identical in its structure and biochemical composition, as well as the processes and mechanisms of dissipation and replacement with new tissue. All materials have a distinct species specificity.

For example, morphogenetic proteins of pigs, horses or cows will never cause cell migration to the focus of inflammation and ectopic osteogenesis in the human body.

Not to mention synthetic materials. For this reason, the use of the latter is seriously limited in the clinical aspect for biological and physiological reasons.

Secondly, more than 50 years of research conducted in this direction with human tissues throughout the world allowed us to identify the most probable and most characteristic diseases and ways to neutralize them in the production of bioimplants.

What can not be said about the tissues of animals: cows, pigs, monkeys, horses.

Spongy encephalitis and other diseases are found in many animals, and the cow is generally a dangerous animal in this respect: more than 80% of the livestock has leukemia.

Methods of analysis of most animal diseases do not exist, therefore, it is not possible to predict the behavior of animal tissues in the human body and the consequences of this for

Methods of analysis of most animal diseases do not exist, therefore, it is not possible to predict the behavior of animal tissues in the human body and the consequences for the health of the patient.

Third, donors are legally (since 1992) subject to the presumption of consent.

That is, the permission of relatives to use tissues of a deceased person at the age of 18-60 years is not required, except for cases when there is a written disagreement submitted in advance or this refusal is regulated by a will of a potential donor.

Finally, fourthly, the safety of the use of human cadaveric material is provided by 6 degrees of protection and multistage pre-cleaning and processing.

Alexey Sharov: How is the selection and processing of human material?

Larisa Volova: The selection, the most thorough and meticulous, begins with the selection of donors.

Patients and agonizing patients are not considered. The remaining donors are tested for viruses (AIDS, hepatitis B, C), syphilis. Everyone is undergoing autopsy. Donors are only those who suddenly die from trauma, mechanical asphyxia and cardiovascular pathology.

The harvested material is subjected to special processing mainly by physical methods (mechanical, ultrasonic, vacuum, radiation, etc.). Only solvents for final degreasing and demineralization are used as chemical agents, and their application is extremely limited.

The technology excludes almost 100% of traces of foreign and technological substances and solvents. The finished material is packaged, sterilized by radiation and stored at room temperature in a dry cool place.

Alexey Sharov: In Europe and in the USA, tissue banks provide not only standard products, but also individual implants. How are things going with you?

Larisa Theodorovna Volova: In addition to one hundred types of standard products, for example, in the form of blocks, cylinders, spongy powder, or crumbs (mineralized or demineralized) from bone tissue, we produce personalized products.

For 2 years now we have been able to produce highly accurate individual bone blocks for dentistry, using data from a patient’s computed tomography to model an individual block and then cut it out on a specialized machine.

Alexey Sharov: How many people are employed in your production?

Larisa Volova: No more than 15 people. Our technologies and equipment allow us to produce material in industrial quantities, without attracting additional personnel.

All employees are highly qualified and have completed the necessary training and internships.

Alexey Sharov: What technical innovations can we expect in the near future?

Larisa Volova: Development of the direction of individual implants for ophthalmology, traumatology, ENT surgery.

Creation of combined cell-tissue grafts.

Alexey Sharov: Where and how can I get acquainted with your product in more detail?

Larisa Volova: First of all on our sites http://lyoplast.com, http://lyoplast.ru and http://russianboneblocks.ru and our key dealers.

Our clinical representatives in Russia are Alexey Sharov and Maria Nosova from St. Petersburg.

Both of them are authors of patents on our materials, are engaged in scientific research and can provide detailed and comprehensive advice on the use of materials in various clinical cases.

Alexey Sharov: Larisa Teodorovna, thank you for the explanations, we congratulate you and your team on the Day of Science, we wish your team further creative success. Until the next meeting!